The warehouse is first registered with an AR Device and the route system is set up. The warehouse manager enters the warehouse list on the web server, or it is automatically transmitted to the web server by the warehouse management system.

Augmented Reality ARKOM ZIM RESEARCH PROJECT

Manual picking expands reality

Rising process efficiency in production and distribution logistics is characterized by constantly increasing automation. Small and medium-sized enterprises (SMEs) in particular are confronted with this development and face a discrepancy between meeting these efficiency criteria and the associated expectations of customers as well as increased investment costs. Especially the processes of order picking show possible optimization potential due to a high personnel intensity.

Thus, companies are often faced with the decision to what extent automation should take place to increase efficiency and how this is compatible with employees and their characteristics of flexibility and dynamism. This problem has been addressed by LIGHTSHAPE as part of the ZIM research project.

Client ZIM Research project

Challenge Development of a pick-by-augmented reality system for the research project ARKOM

Highlights Development of a flexible and cost-effective pick-by-augmented reality system without infrastructure intervention.

Technology Augmented Reality

Devices Hololens 2

Partner Institute for Materials Handling and Logistics (IFT)

Our solution By means of Pick-by-AR

Solution by means of AR

The picker is supported in the warehouse by data glasses and augmented reality content in the picking activities. The goal of the research project is not to replace humans in order picking with automation, but to combine the capabilities of humans with automation and to improve the processes.

Focused on the application area of SMEs, the research project pursues the goal of realizing a flexible and cost-effective pick-by-augmented-reality system.

Functionality

A digital image of the environment is created by the data glasses. With the help of the data glasses, "anchors" are placed in the room to measure the space and create a 2D image. Through attached QR codes at the storage locations, the data glasses create the 3D image and store it.

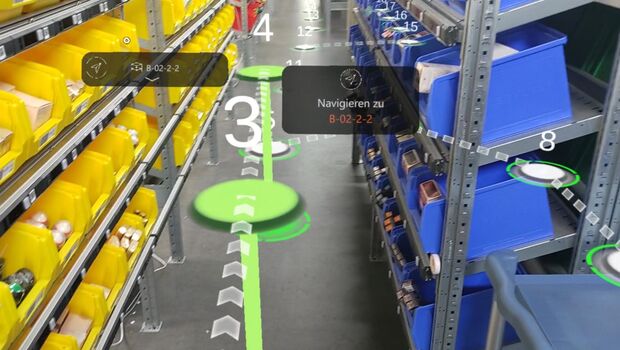

Thus, a digital image of the warehouse is created by the data glasses alone without any further infrastructural interventions. With this digital image as a basis, the routes of the order pickers through the aisles are planned and optimized. The order picker is shown the next storage location and the route to it.

Process

General setup

AR Device

The picker receives the list with automatically optimized sequence directly on the AR device. In the AR device, the picker is shown the respective path to the nearest product/storage location as a graphical overlay.

Processing the list

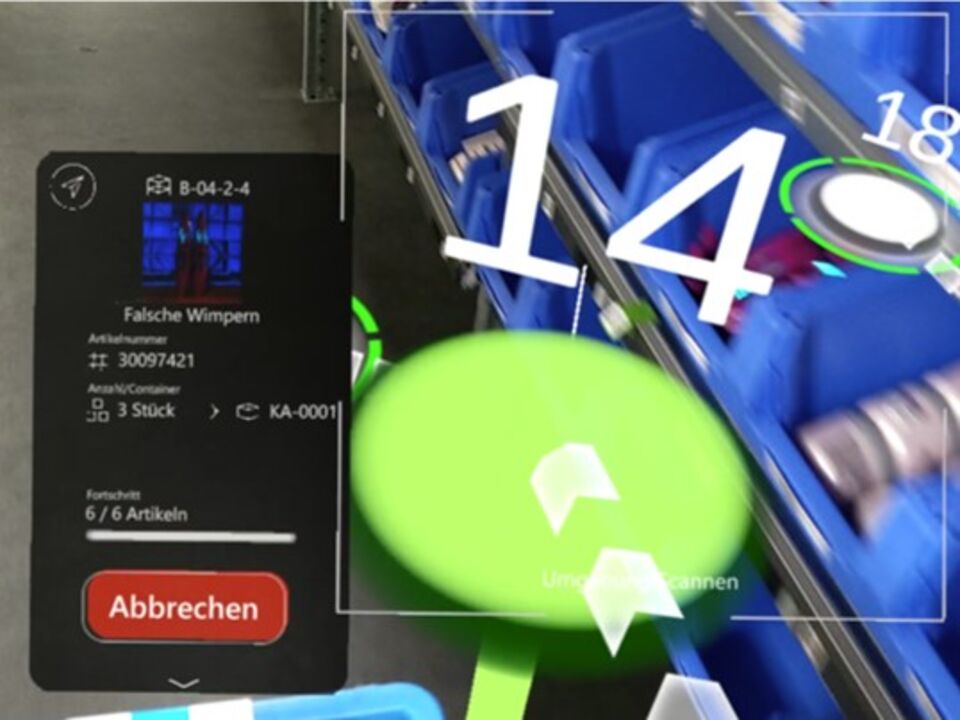

At the storage location, a product image with quantity information appears, which the picker can check off according to the collected products. As soon as this has been checked off, the next product is displayed and the picker is also guided there until the list has been completely processed.

End

At the end, the products are placed at the destination and the picker receives a new list.