VR training application Employee training in VR for tool maintenance and repair

Training / Staff training / Maintenance

VR training to increase the efficiency of service on complex machines and tools

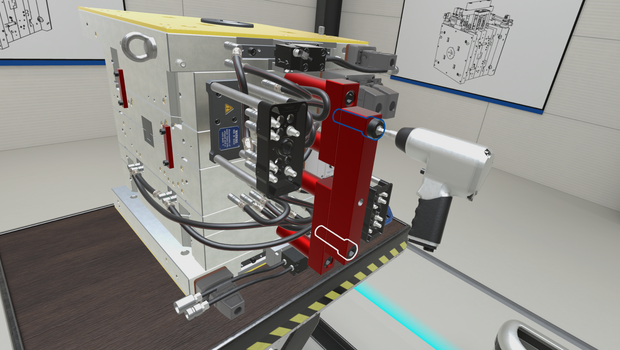

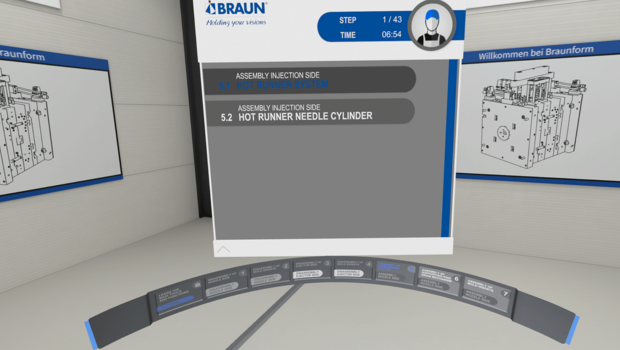

Braunform GmbH in Bahlingen is a strategic partner in the field of injection molds. The assembly and disassembly process for cleaning and maintenance of the injection mold is very complex and involves many work steps that require accuracy as well as prior knowledge. The complexity of the process often leads to errors and damage to the tool. In order to minimize these errors and damages, LIGHTSHAPE developed a VR training application that trains these processes on a digital twin in a realistic working environment. VR training applications are particularly suitable for complex and cost-intensive industrial machines and tools because all disassembly and assembly steps can be trained safely and as often as desired.

Service, times and costs are significantly reduced. A faster restart of production is guaranteed. In this application, the technician is guided through the maintenance and repair using instruction boards. If desired, a "foreman avatar" shows the work steps to be performed.

In an upstream tutorial mode, it is possible to practice with the assembly tools to be used later on the injection moulding tool. Descriptions attached to the virtual tools explain their use.

Client

Braunform GmbH