From manual to automated workflow

Manual labor Our workflow so far

Nowadays, more and more companies are relying on interactive applications to stage their products. There is a good reason for this: interactivity creates an emotional bond. Our customers therefore have high expectations of the detailed and lifelike presentation of their products - and rightly so!

Unfortunately, product presentation in high visual quality is often accompanied by an increased demand for computing power. However, not every end consumer has the latest high-end hardware at hand, but owns a standard smartphone or tablet, for example. So how does the realistic product display get onto the personal smart device?

The answer to this is simultaneously simple and yet complex: the data must shrink. This is done at LIGHTSHAPE through a process called "retopologization". In this process, the virtual object's interface is reworked and simplified. For a possible workflow in this category, see our blog article "From CAD data to low poly models for interactive applications".

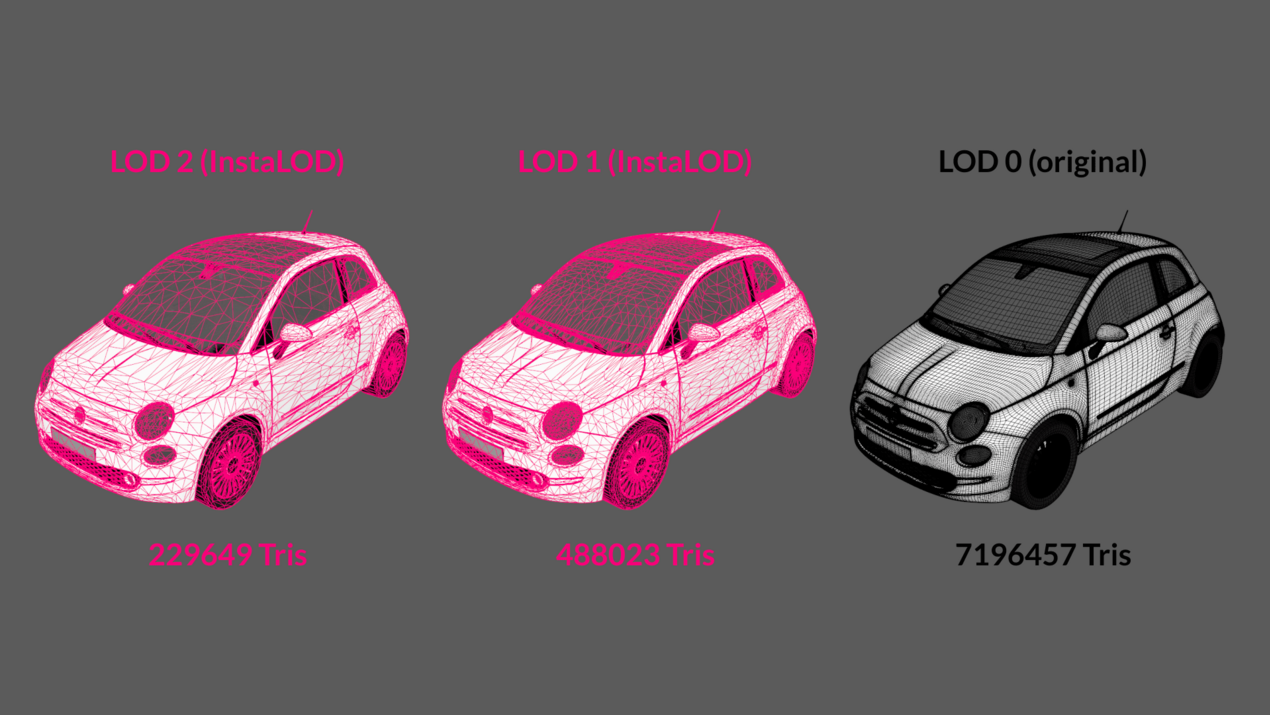

So-called "LODs" (Levels of Detail) are also used. These are more computationally efficient variants of an object that are displayed when the object is far away. This actually saves computing time for the display of details that would not be visible anyway. Especially when many objects are to be seen at once, LODs ensure a smooth frame rate.

Both retopologization and the generation of LODs, done by hand, are extremely time-consuming. In the latter case, the object must even be optimized several times. For example, scaling down the many technical components of a modern electric vehicle so that they can be displayed without problems on a mobile device or on the web takes more than a month - and that with several graphic designers involved. After all, all the parts have to be rethought down to the last detail and their surfaces have to be recreated, be it gear wheels of the rear axle transmission, cables of the charging device or connections of a voltage transformer.

Comparison of multiple LOD versions

Partial automation Our new workflow

It is no wonder that high costs are incurred in such an undertaking. Moreover, during all this time, customer feedback can only be implemented with difficulty, if at all. The later a change request arises, the more work steps have to be iterated again. This creates a bottleneck that slows down the constructive and valuable exchange between service provider and customer.

In our ongoing search for promising solutions, we are constantly addressing the issue of automation. However, it is clear to us that we want to continue to offer our customers the quality for which we stand with our name. Many automated workflows do not meet these requirements.

While they enable extremely timely implementation, unlike our employees they cannot take into account which details our customers place particular emphasis on and which objects are generally essential for the appearance of the product.

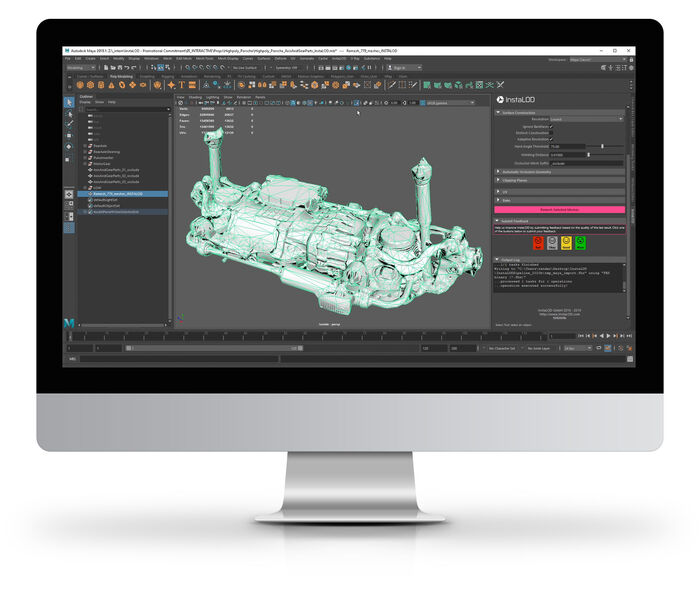

Since we cannot do without the speed of automated solutions or the quality of human experience and judgment, we use partial automation. InstaLOD software performs our retopologizations by taking into account numerous detailed settings of our graphic designers and intelligently calculating the result. In this way, an appropriate solution can be found for each individual product.

Automatisation of Workflows Look into the future

Looking ahead, we see that workflow automation is far from reaching its limits. In an ideal future, we will simply feed in the product's data, watch it move through a scripted pipeline, and get the high-quality result so that we can deliver it.

Already, a trend toward fully integrated systems is emerging. Increasingly large parts of the workflow are being managed holistically to reduce the use of different programs, file formats and conventions. As a result, we will avoid compatibility problems in the future, be able to manage data much more clearly, and become faster and more efficient by eliminating intermediate steps. For example, InstaLOD is already designed to run through a complete workflow. The 3D suite Blender also follows a concept in which the user does not have to leave the software for the various steps.

Furthermore, for companies like LIGHTSHAPE that value individual customer wishes, communication between man and machine continues to be a crucial point. Similar to the design of colors and shapes or the unobtrusive conversion of image formats, we have to learn how an eye perceives the virtual object and at which points a reduction of details does not reduce the overall quality.

Aesthetics are difficult to evaluate, and anything that can't be detected with artificial intelligence, graphic designers must be able to accurately communicate to it: What is important to the customer? In what context is the product shown? How will it be interacted with? The more precisely and intuitively this exchange works, the more likely the result will match our customers' vision. And that's what we're working toward. By cleverly combining progress and interactive multimedia, we at LIGHTSHAPE create a sustainable model to realize your project.